What Is The Difference Between A Grinder And A Hammer Miller?

In modern agricultural processing, grain grinders and hammer millers play a crucial role in raw material preparation. Many customers often ask: What’s the difference between a grinder and a hammer mill?

While both machines are used to grind crops into powder, their internal structures, working principles, and even the final product are quite different. Understanding these differences is beneficial when purchasing such equipment.

Internal structure comparison

Corn grinding mill

Grinding mill structures typically use grinding discs, grinding rollers, or fixed and rotating grinding discs.

Materials are ground through pressure and friction between two surfaces. Some specialized grinding mills operate at high speeds to achieve ultrafine grinding.

Structural Features:

- Compact structure

- Precision grinding components

- Smaller output size

- Lower impact force

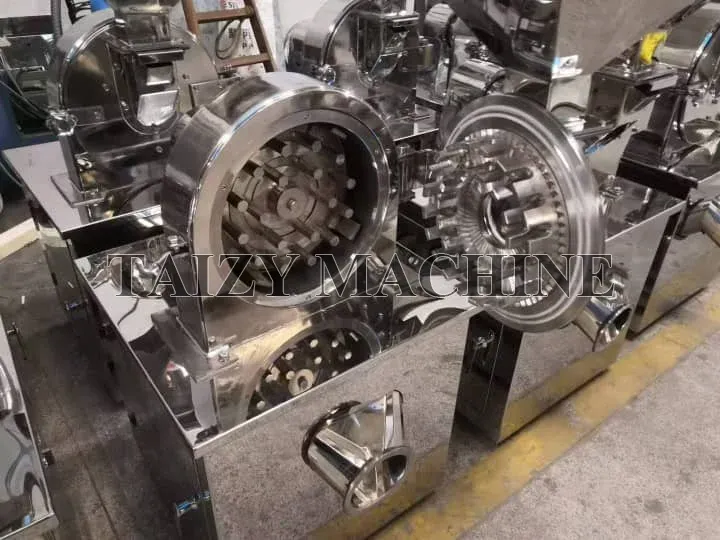

Hammer miller

A hammer miller mainly consists of a feed inlet, a high-speed rotating rotor, multiple swinging hammers, a screen, and a discharge outlet.

Its core component is the rotor with hammers. When the rotor rotates at high speed, the hammers repeatedly impact the material until it is crushed small enough to pass through the screen.

Structural Features:

- High-speed impact system

- Replaceable hammers

- Adjustable screen size

- Powerful crushing capacity

Due to its powerful impact force, the hammer mill is more suitable for coarse to medium crushing operations.

Differences in working principles

Grinding mills utilize the relative motion between a high-speed rotating toothed disc and a fixed toothed disc to pulverize materials through a combination of impact, shearing, friction, and collisions between materials.

Hammer crushers work by rapidly breaking down materials under mechanical force through high-speed impact, collision, and repeated hammering. The final particle size depends on the mesh size of the screen.

Differences in finished product effects and uses

Grinding mills produce extremely fine particles with a delicate texture, suitable for refined flour or spice powders, with a fineness of 20-120 mesh.

Hammer mills produce a wide range of particle sizes (from coarse to medium powder) and operate at high speed, making them ideal for livestock feed processing.

How to determine whether to choose a corn grinder or a hammer miller?

If you need ultrafine powder or a finely textured finished product, then Taizy’s stainless steel grinder is a great choice.

If you are only roughly processing dry grains or biomass for feed production or resource recycling, then a hammer mill is the most cost-effective investment.

Contact us to get the machine best suited for you!

While both grinders and hammer mills can reduce material size, their structures, operating principles, and applications differ significantly.

Grinders focus on fine grinding, while hammer mills emphasize high-speed impact crushing and high production efficiency.

For feed production, biomass processing, and large-scale grain crushing, hammer mills are often a more efficient and economical choice.

If you are looking for specialized hammer mill equipment for your production line, selecting the right model based on capacity and material type is crucial to maximizing performance and profitability.

Still unsure which one is right for you? Please provide your raw materials and desired finished product, and our professionals will provide you with the best advice.