آلة تنظيف الحبوب الأوتوماتيكية بالكامل مع الرياح - ناقل مُنقل

آلة تنظيف الذرة | آلة تنظيف الحبوب المتعددة

الموديل: FSQDJ-57، FSQDJ-100

الإنتاج: 400-1200 كجم/ساعة

الطاقة الداعمة: 3-4 كيلووات

الحجم: 1700*800*2900 مم

الوزن: 300 كجم

المواد: القمح، الذرة، الحنطة السوداء، الدخن، إلخ.

تُستخدم هذه الآلة لتنظيف الحبوب دائمًا كخطوة أولى قبل معالجة المحاصيل. وظيفتها الرئيسية هي فصل الغبار والحصى والحبوب الذابلة وغيرها من الشوائب. يمكنها معالجة المواد الخام من 400 إلى 1200 كجم كل ساعة.

مع نظام آلي عالي، فإن آلة تنظيف الحبوب المتعددة سهلة التشغيل. بالإضافة إلى ذلك، فهي صغيرة الحجم وتستهلك طاقة منخفضة، لذا فهي خيار مثالي لمصنعي الحبوب الخام، ومصانع معالجة الطعام، والمزارع الصغيرة.

ما هي المزايا الكبيرة لآلة تنظيف الحبوب المتعددة؟

- آلة تنظيف الحبوب هي تلقائي بالكاملبعد تشغيله، سيقوم جهاز التغذية بتحويل المواد الخام إلى نظام التنظيف وإكمال العمل. لسهولة الاستخدام، قمنا بتصميم نظام تشغيل بسيط. حتى إذا كنت لا تعرف هيكل الآلة، يمكنك البدء بسرعة!

- لديها نظام تصفية علمي لفصل النفايات والمنتجات. علاوة على ذلك، هناك ثلاثة مخرج مصممة لتمييز المواد الناتجة. مزودة بمروحة، تحتاج المادة الخام إلى التنظيف مرة واحدة فقط، مما يمكن أن يلبي متطلبات المعالجة.

- بفضل حجمها المدمج، فإن آلة تنظيف الذرة هي مناسب لأي موقفيمكن تثبيته في ورشة إنتاج صغيرة أو دمجه مع آلات إنتاج أخرى لإنشاء خط إنتاج كامل لمعالجة المحاصيل.

المعلمات الفنية لآلة تنظيف حبوب القمح

هناك نموذجين من هذه الآلة لتنظيف الحبوب المتعددة، ويمكنك اختيار واحد وفقًا لاحتياجاتك من سعة الآلة. فيما يلي معلماتها التفصيلية.

| نموذج | FSQDJ-57 | FSQDJ-100 |

| الإخراج | 400-600 كجم/ساعة | 800-1200 كجم/ساعة |

| الطاقة الداعمة | 3 كيلو واط | 4 كيلو واط |

| مقاس | 1700*800*2900 مم | 1900*1000*3000 مم |

| وزن | 300 كجم | 400 كجم |

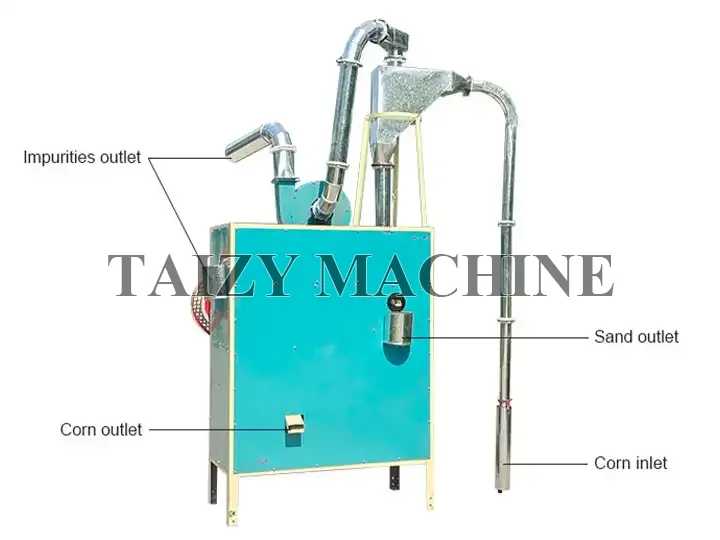

الهيكل الكامل لآلة تنظيف الذرة

تتكون الهيكل الخارجي لآلة تنظيف الحبوب بشكل رئيسي من عدة مخرجات (بما في ذلك مخرجان للشوائب، ومخرج واحد للرمال، ومخرج واحد للحجارة)، ومروحة واحدة، ومدخل واحد، وأحزمة ناقلة.

نظام التشغيل الخاص به مقسم بشكل رئيسي إلى أربعة أجزاء: جهاز التغذية التلقائية، جهاز الشاشة المهتزة ذات الطبقتين، جهاز إزالة الحجارة ذات الكثافة المحددة، وجهاز تنظيف القمح.

- جهاز التغذية التلقائي مسؤول عن تحويل الحبوب الخام إلى نظام المعالجة. وهو مزود بمروحة واحدة لتسهيل التشغيل التلقائي.

- جهاز الشاشة الاهتزازية ذات الطبقتين يهدف إلى إزالة الغبار والرمال وغيرها من الشوائب الصغيرة والخفيفة.

- جهاز إزالة الحجارة ذو الكثافة المحددة هو جزء لا غنى عنه لإزالة الحطام الأثقل (مثل الحجارة الصغيرة).

- جهاز تنظيف القمح يستخدم خصيصًا لفصل قش القمح ونخالة القمح والحبوب المشوهة.

لماذا من الضروري امتلاك آلة تنظيف الحبوب الأوتوماتيكية؟

- إذا كان لديك خط لمعالجة الحبوب وترغب في تقليل تكلفة شراء المواد الخام، يمكنك إضافة آلة تنظيف الحبوب كخطوة أولى لتنظيف المواد. يمكنك معالجتها بنفسك، مما يلغي الحاجة لدفع تكاليف تنظيف ومعالجة المواد الخام.

- هل ستشعر دائمًا بالانزعاج عند تنظيف الذرة والقمح من حصاد المزرعة؟ يمكن لهذه الآلة مساعدتك في حل المشكلات بسهولة. يمكنها فصل قش القمح والحصى وحتى الغبار عن محاصيلك.

- كمورد للمواد، فإن السلع النظيفة وعالية الجودة هي دائمًا الخيار الأول للعملاء. يمكن لهذه الآلة تصفية المحاصيل ذات الجودة الرديئة.

في الجزء التالي، سأعرض لك المنتجات التي يمكن إنتاجها والاستخدام المحدد للآلة.

منتجات وآلات تنظيف الحبوب وتطبيقاتها

كآلة لتنظيف الحبوب متعددة الوظائف، يمكنها تصفية وتنقية الحطام من مختلف الحبوب، مثل الحنطة السوداء، والذرة، والدخن، والقمح، وغيرها.

الوظيفة الرئيسية لآلة تنظيف الحبوب هي انتقاء الحبوب عالية الجودة لتسهيل معالجة الطعام اللاحقة. هذه المواد المعالجة واضحة بما يكفي للبيع. ولكن إذا كنت مهتمًا بخلق المزيد من الفوائد، أود أن أقدم لك بعض المعدات المفيدة.

أدناه، سأقدم خط إنتاج أعتقد أنه سيساعدك على فهم عملية إنتاج منتج غذائي زراعي كامل.

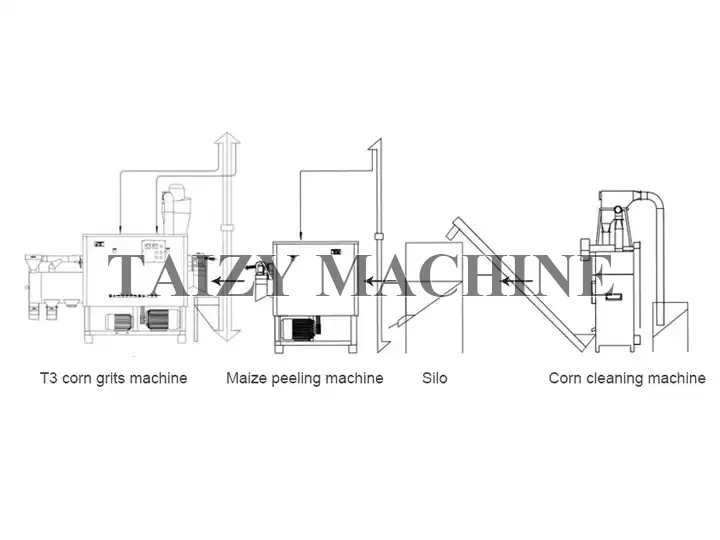

خط إنتاج لمعالجة الذرة

هذه وحدة كاملة لآلة طحن الذرة لصنع دقيق الذرة، وتتكون من أربع أجزاء رئيسية: آلة تنظيف الحبوب، صومعة، آلة تقشير الذرة، وآلة دقيق الذرة T3.

إنها العملية الكاملة لإنتاج دقيق الذرة مع تحكم آلي ممتاز وكفاءة إنتاج عالية للغاية. يمكن أن يحسن سعر منتجاتك، والتي يمكن توفيرها للسوبرماركت، وأسواق الجملة للمزارعين، وحتى لبعض مصانع الأغذية التي تحتاج إلى مثل هذه المواد لمعالجة الطعام.

إذا كنت مهتمًا بهذه الآلة أو لديك العديد من الأسئلة الأخرى، اتصل بنا لمعرفة المزيد من التفاصيل!