Faucheuse de maïs ensilé

| Modèle | Type à roues, type à chenilles |

| Puissance du moteur | 100-150HP |

| Largeur de coupe | 1400-1800mm |

| Capacité du godet | 3,1 m³ |

| Longueur de segment de coupe conçue | 10-40 mm |

| Vitesse de travail | 1–3 km/h |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

L'ensileuse de maïsrésout principalement les problèmes de récolte des tiges de maïs dans les zones vallonnées. Équipée d’un moteur de 110,3 kW (150 HP), cette machine a une largeur de coupe de 1550 mm et une vitesse de travail de 1–3 km/h, pouvant récolter environ 0,3–0,5 hectare par heure.

En plus des tiges de maïs, notre ensileuse peut également traiter la plupart des autres herbes fourragères, des légumineuses, et des céréales. La longueur de coupe est réglable de 10 à 40 mm, adaptée aux différents besoins des fermes d’élevage.

Quelles sont les caractéristiques de l'ensileuse de maïs Taizy ?

- La conception robuste du châssis offre une meilleure stabilité et une capacité de charge élevée. Pour être adaptée aux zones humides, vallonnées, souples, et autres conditions, nous avons également conçu un modèle à chenilles.

- La hauteur de la tête peut être ajustée pour convenir à la récolte d’ensilage de maïs, d’herbe naipère (≤ 2,5–3 m), et autres cultures fourragères à haute valeur nutritive, en fonction de la hauteur de la culture et des conditions du champ.

- La longueur initiale de la coupe d'herbe est standard à 15 mm et peut être ajustée dans une plage de 10-40 mm (selon le nombre de lames et la vitesse de coupe) pour assurer une bonne qualité d'ensilage et faciliter la digestion des ruminants.

- L’ensileuse de tiges de maïs utilise un système de déchargement hydraulique, ce qui facilite le déchargement. Elle est également équipée d’un réservoir de 3,5 mètres cubes, pouvant charger environ 1 tonne par lot, ce qui la rend adaptée à la récolte de grandes quantités d’herbe.

- Les ensileuses de maïs Taizy sont disponibles en configurations moteur de 100HP, 150HP et 160HP pour répondre aux différentes échelles de production et exigences de rendement des clients.

Structure détaillée de l'ensileuse de tiges de maïs

La machine se compose de quatre systèmes : le système de puissance et de mobilité, le système d’alimentation et de coupe, le système de collecte et de décharge, et le système de contrôle et de sécurité.

1. Système de puissance et de mobilité

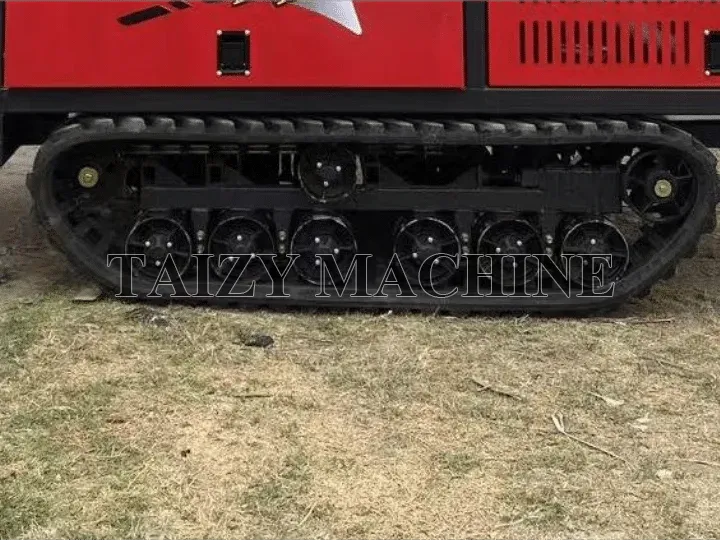

Le moteur diesel fournit la force motrice principale pour la récolte et la coupe, avec des options de puissance de 100, 150 et 160 ch. Les chenilles ou grandes roues en caoutchouc assurent une opération stable sur terrain boueux ou accidenté.

Dans une ensileuse à chenilles, les roues motrices transmettent la puissance du moteur pour entraîner les chenilles. Les tendeurs ajustent la tension des chenilles pour assurer un fonctionnement fluide, et les roues de support aident à supporter le poids de la machine et à maintenir l’équilibre.

2. Système d’alimentation et de coupe

Ce dispositif de collecte de l’ensileuse de maïs, aussi appelé fourche de collecte de paille de maïs, guide principalement la paille de maïs vers la tête. Le cylindre de levage de la tête ajuste la hauteur de la tête en fonction des conditions de la culture, s’adaptant aux exigences de récolte variables.

Les lames de coupe peuvent être ajustées par le nombre, principalement pour couper la paille lors de l’opération. Ensuite, le tambour de récolte tire la paille dans la tête pour un traitement supplémentaire. Enfin, le système de coupe et de broyage déchiquette les tiges en petits morceaux pour l’ensilage ou les renvoie au champ.

3. Système de collecte et de décharge

Cette partie comprend principalement le réservoir de stockage (collecte des tiges de maïs hachées) et le conduit de décharge (transfert des matériaux hachés vers la remorque ou leur dispersion sur le champ).

Ainsi que le cylindre du réservoir de stockage (contrôle de la levée/décharge du réservoir) et le cylindre du conduit de décharge (ajuste la direction/l’angle du conduit pour une décharge précise).

4. Système de contrôle et de sécurité

La station de l’opérateur est l’endroit où le conducteur contrôle la récolte, la conduite et le déchargement, avec un pare-soleil qui protège contre le soleil et la pluie.

Comme les machines agricoles traditionnelles, nos ensileuses de maïs sont équipées de miroirs rétroviseurs, améliorant grandement la visibilité et la sécurité lors de l'utilisation.

Deux types d’ensileuses

1. Le moissonneuse de maïs ensilage à crawler

Avantages

Notre ensileuse de maïs à chenilles fonctionne bien sur terrain boueux, humide ou vallonné. En raison de sa plus grande surface de contact, elle compacte moins le sol.

De plus, elle offre une conduite très stable et une traction excellente, ce qui la rend plus adaptée aux grandes exploitations qu’aux machines à pneus.

Paramètres

| Modèle (type autopropulsé) | 4QZL-1400 | 4QZL-1800 |

| Puissance du moteur | 100-150HP | 150HP |

| Vitesse nominale du moteur | 2400r/min | 2400r/min |

| Largeur de coupe | 1400mm | 1800mm |

| Type de coupeur de tête | Lame de disque | Lame de disque |

| Mécanisme d'alimentation | 4 unités | 4 unités |

| Système de transmission | Transmission hydraulique | Transmission hydraulique |

| Largeur de la tête | 280/350mm | 280/350mm |

| Longueur de contact au sol de la chenille | 1400mm | 1400mm |

| Écartement des rails | 1240mm | 1240mm |

| Capacité du godet | 3,1 m³ | 3,1 m³ |

| Longueur de segment de coupe conçue | 15mm | 15mm |

| Dimensions | 5200mm*1520mm*3800mm | 5200mm*1520mm*3800mm |

2. L'ensileuse de maïs à roues

Avantages

Ce type d’ensileuse de maïs a une vitesse de route plus élevée (20-40 km/h) et une consommation de carburant plus faible sur terrain sec/plat. Facile et peu coûteux à entretenir (remplacement des pneus plus simple). Convient donc aux exploitations dispersées, aux champs secs et plats, et à ceux qui doivent se déplacer fréquemment par la route.

Paramètres

| Modèle (type autopropulsé à roues) | 4QZL-1400 | 4QZL-1800 |

| Puissance du moteur | 100-150HP | 150HP |

| Vitesse nominale du moteur | 2400r/min | 2400r/min |

| Largeur de coupe | 1400mm | 1800mm |

| Type de coupeur de tête | Lame de disque | Lame de disque |

| Mécanisme d'alimentation | 4 unités | 4 unités |

| Système de transmission | Transmission hydraulique | Transmission hydraulique |

| Empattement | 2150mm | 2150mm |

| Largeur de la chenille | 1300mm | 1300mm |

| Capacité du godet | 3,1 m³ | 3,1 m³ |

| Longueur de segment de coupe conçue | 15mm | 15mm |

| Dimensions | 5200mm*1520mm*3800mm | 5200mm*1520mm*3800mm |

Application de l’ensileuse de maïs

Cette ensileuse de maïs est principalement utilisée pour récolter et couper les tiges de maïs et autres cultures en ensilage pour le bétail comme les vaches laitières, les bovins et les moutons.

Un ensilage de maïs de haute qualité peut augmenter l’efficacité de la production de lait et de viande. Il est donc largement utilisé dans les grandes exploitations laitières, les fermes de bœuf, et les entreprises de contractance agricole. Les entrepreneurs utilisent des ensileuses pour fournir des services de récolte aux fermiers locaux.

De plus, les tiges de maïs hachées peuvent être utilisées comme matière première pour la production debiogaz. La fermentation de l’ensilage de maïs génère de l’énergie renouvelable, fournissant une source d’énergie respectueuse de l’environnement.

Dans d’autres régions, les ensileuses coupent les tiges pour un retour direct au champ, améliorant la matière organique du sol, la fertilité, et réduisant la pollution par la combustion.

Retour des clients sur cette ensileuse de fourrage

Ferme malaisienne ayant importé la machine d’ensilage Taizy

Une ferme laitière de taille moyenne à Johor Bahru, en Malaisie, avec environ 300 vaches, a rencontré un défi : le coût élevé de l’achat d’ensilage importé et l’inefficacité de la coupe manuelle des tiges de maïs.

Pour réduire les coûts et améliorer la qualité de l'alimentation, la ferme a décidé d'installer une ensileuse de maïs Taizy. Avec cette nouvelle machine, ils peuvent récolter plus efficacement le maïs local, le couper en ensilage fin, et le stocker dans des silos pour une utilisation à long terme.

Cela garantit non seulement une alimentation stable pour les vaches, mais réduit aussi la dépendance à l’égard des aliments importés coûteux. Le propriétaire de la ferme a déclaré que l’ensileuse Taizy est un outil précieux pour les petites et moyennes exploitations malaisiennes cherchant à se moderniser, en économisant efficacement les coûts et en améliorant la qualité de l’alimentation.

Établir une coopération avec les usines de transformation de l’alimentation indiennes

Une usine de moulée à Punjab, en Inde, a contacté Taizy pour améliorer sa chaîne d’approvisionnement. La société produit des balles d’ensilage de maïs emballées et les distribue à des milliers d’éleveurs laitiers dans la région. Après discussions détaillées, Taizy a fourni une solution d’ensileuse adaptée aux variétés de maïs indiennes et aux conditions de terrain.

La nouvelle machine a triplé la vitesse de récolte et de traitement de l’ensilage de la ferme, assurant une alimentation hautement nutritive pour les fermiers locaux. Ce partenariat a également permis à la ferme d’étendre ses activités, en exportant des balles d’ensilage vers les états voisins et même le Bangladesh.

Si vous souhaitez collaborer avec Taizy, n’hésitez pas à nous contacter !

Pour le quota gratuit et la liste des produits concernant notre ensileuse de maïs, consultez-nous simplement !