Rocchiatore di mais per la trebbiatura dei cereali

Macchina trebbiatrice di frumento | Macchina rimuovi-seme di mais

Modello: MT-1500

Potenza: 15-18hp (motore diesel), 7,5 kW (motore elettrico)

Applicazione: mais, frumento, soia, riso, ecc.

Capacità: miglio 3 t/ora, mais 5 t/ora, riso e frumento 2 t/ora.

Paesi ad alta domanda: Nigeria, Zimbabwe, Pakistan, ecc.

Attraverso ricerche e aggiornamenti, Taizy ha progettato un nuovo modello di macchina spellatrice di mais, che supporta due opzioni di alimentazione: diesel e motore elettrico. Dotata di un sistema a doppia ventola, può rimuovere le impurità in modo più efficiente, rendendo il mais finito più pulito e di qualità superiore.

Inoltre è ampiamente utilizzato anche per separare soia, sorgo, miglio, riso, ecc. La macchina ha camere di lavoro doppie, il che rende la produzione più efficiente: 3 t/ora (miglio), 5 t/ora (mais), 2 t/ora (riso e frumento).

Caratteristiche aggiornate del nuovo stile di macchina spellatrice di mais

Dopo gli aggiornamenti di prodotto, le nostre macchine hanno fatto progressi significativi rispetto ai modelli precedenti.

- Questa nuova trebbiatrice per mais subisce due processi di trebbiatura, ciò che la differenzia dal vecchio modello, aumentando il tasso di trebbiatura e la pulizia della trebbiatura.

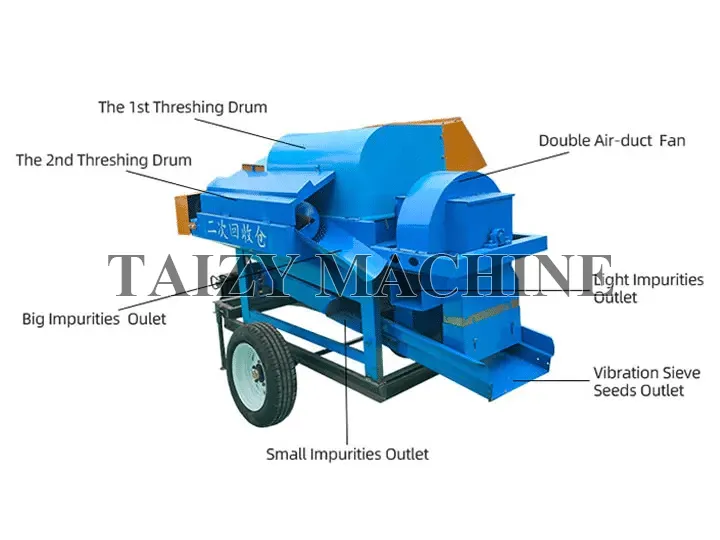

- Il nuovo modello ha tre uscite diverse: una grande uscita di rifiuti con setaccio, una piccola uscita di rifiuti con ventola e l'uscita del prodotto finale.

- La nostra spellatrice di mais è dotata di ventole duali, che offrono migliori effetti di pulizia, tassi di rottura del mais inferiori e maggiore adattabilità a vari raccolti e livelli di umidità rispetto ai modelli con ventola unica.

Struttura della nostra spellatrice multifunzione di mais

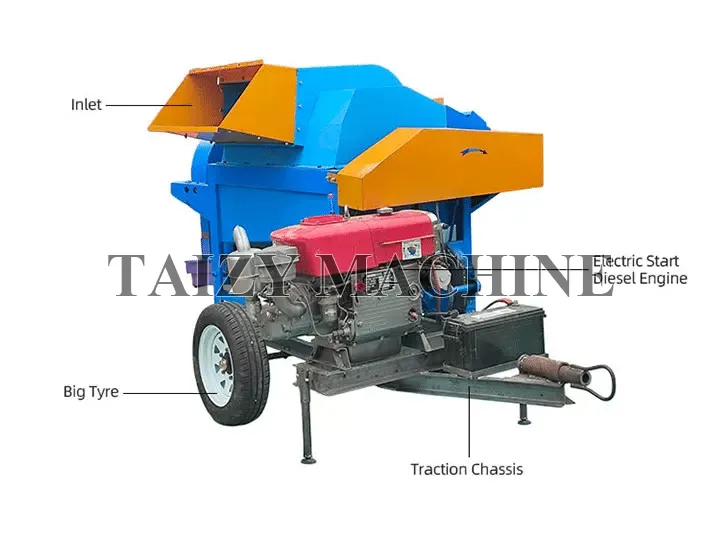

La nostra trebbiatrice di frumento è composta da ingresso, motore diesel (o motore elettrico), pneumatico mobile, telaio di trazione, tamburi di trebbiatura, uscite e ventola sir-duct.

Nella nostra spellatrice di mais ci sono 2 tamburi di trebbiatura. Il primo tamburo è responsabile della trebbiatura iniziale, che separa i chicchi di mais dalle spighe mediante attrito e impatto. Il secondo tamburo esegue una separazione più fine che migliora l'efficienza complessiva della trebbiatura e la purezza.

Il sistema a doppia ventola è una delle principali caratteristiche di questa spellatrice di mais. La prima ventola rimuove grandi bucce e impurità leggere, mentre la seconda ventola offre una separazione con aria secondaria per polveri e paglia più piccole. Questo sistema di flusso d'aria in due fasi garantisce che i chicchi finali siano più puliti e di qualità superiore.

Per facilitare gli spostamenti tra i campi, la nostra spellatrice di mais è progettata con pneumatici grandi e durevoli, che la rendono adatta sia a operazioni stazionarie sia in campo, aumentando la flessibilità per utenti in aziende agricole rurali o di grandi dimensioni.

Quali sono le applicazioni della spellatrice di mais?

Oltre al mais, questa trebbiatrice versatile può essere utilizzata anche per una varietà di cereali e colture, tra cui mais, sorgo, miglio, soia e frumento, soddisfacendo un'ampia gamma di esigenze di lavorazione dei cereali.

Gli spellatori di cereali sono ampiamente utilizzati in aziende agricole rurali, cooperative agricole, stazioni di acquisto grano e piccoli impianti di lavorazione alimentare. Aiutano a ridurre la manodopera e i relativi costi, migliorando significativamente l'efficienza della trebbiatura.

Taizy ha ricevuto numerosi ordini da regioni in cui mais e altri cereali sono alimenti di base, come Africa, Sud-est asiatico e Sud America. Questa macchina svolge un ruolo vitale nel migliorare l'efficienza di lavorazione dei cereali e nel sostenere la produzione alimentare locale.

Quanto costa una spellatrice di mais Taizy?

Una trebbiatrice di base per mais costa tipicamente meno di USD 399,304,585,21,000, ma per i prodotti destinati all'esportazione, molti fattori possono influenzare il prezzo finale, spaziando da USD 399,304,585,21,000 a USD 399,304,585,22,000.

I seguenti fattori possono influire sulla differenza di prezzo finale:

- Spedizione e trasporto: include il trasporto marittimo, il trasporto interno e la gestione del porto.

- Doganze e tasse: consistono in dazi doganali, tasse d'importazione e tasse di ispezione nel vostro paese.

- Opzioni di trasmissione: scegliere un motore diesel o elettrico può influire sul costo.

Se siete interessati alle nostre macchine, mettetevi in contatto con noi per un preventivo in modo da comprendere appieno l'investimento. Accogliamo anche preventivi personalizzati basati sul vostro paese, tipo di energia, requisiti di capacità e condizioni di spedizione.

Il processo di acquisto della nostra trebbiatrice per mais

Il nostro obiettivo è fornire a ogni cliente un'esperienza di acquisto fluida ed efficiente. Di seguito è riportato il processo di acquisto, per aiutarvi a comprendere l'intero processo dalla produzione alla consegna della macchina.

Passo 1: Il nostro personale di vendita professionale identificherà il modello appropriato in base alle informazioni del cliente, tra cui tipo di cereale, requisiti di capacità e opzioni di potenza. Forniremo quindi dettagli tecnici, video operativi e un preventivo per riferimento dei clienti.

Passo 2: Una volta confermati i dettagli dell'ordine, la produzione può iniziare dopo il pagamento del deposito. La nostra fabbrica organizzerà la produzione secondo le specifiche. Dopo l'assemblaggio, ogni macchina spellatrice di mais verrà testata per garantire prestazioni stabili e funzionamento regolare.

Passo 3: Prima della spedizione, i nostri tecnici effettueranno un test completo, registreranno video e confermeranno con il nostro cliente. Solo dopo la conferma passeremo alla fase successiva.

Passo 4: Una volta che il cliente ha pagato il saldo rimanente, organizzeremo l'imballaggio, lo sdoganamento esportazione e la consegna al porto di carico. Se necessario, il nostro team può assistere anche nello sdoganamento per snellire l'importazione.

Taizy esporta da oltre un decennio e ha le nostre proprie fabbriche, impegnandosi a offrire i migliori prezzi e la migliore qualità ai nostri clienti. Se siete interessati alle nostre macchine spellatrici di mais, non esitate a contattarci per un preventivo gratuito!

Se vuoi elaborare ulteriormente il prodotto finito, forniamo anche: