Fresh Corn Sheller Machine | Sweet Corn Peeler Machine

| Brand | Taizy Machinery |

| Power | 1.2kw |

| Voltage | 220V |

| Capacity | 400-500Kg/h |

| Speed of conveyor | V=15m/min |

| Machine size | 1150*500*1300mm |

You can now ask our project managers for technical details

Taizy SUS304 fresh corn sheller machine is used to peel the kernels of fresh corn and sweet corn without damaging them. The speed of threshing with the automatic sweet corn peeler is so fast that it can shell 400-500 kg of kernels per hour.

It is commonly used in corn processing plants, corn canning production plants, and frozen food production plants etc. Multiple sweet corn husking machines can be used with large assembly lines, which are necessary machines for corn processing enterprises.

Working video of fresh corn sheller machine

Technical parameters of corn thresher for sale

| Model | TZ-268 TZ-368 |

| Power | 1.2kw |

| Voltage | 220V |

| Capacity | 400-500kg/h seed (Feeding about 75 ears of corn per minute) |

| Speed of conveyor | V=15m/min |

| Machine size | 1150*500*1300mm |

We also provide a model of TZ-368, which has the same specifications as TZ-268. But it is equipped with a conveyor for a quicker speed of feeding. Besides, the whole fresh corn sheller machine is made of SUS404. So if you have high standards for your products, Taizy baby corn thresher machine can perfectly meet your needs.

Advantages of fresh corn sheller machine

- This fresh corn sheller machine can be used for a wide range of raw materials, and it can smoothly thresh all types of sweet corn and sticky corn.

- The knife inside the sweet maize thresher machine has high hardness, good wear resistance, and a long sharpening cycle, having undergone several research and development stages to significantly improve production efficiency.

- Corn kernel cutting is smooth and dry, and the machine does not damage the waxy corn kernels, high rate of corn kernel removal.

- The depth of the fresh corn kernels is adjustable, allowing it to meet the different needs of various users.

Application of fresh corn sheller machine

This sweet corn sheller machine is designed for fresh corn husking work, suitable for various types of corn, including sweet corn, fruit corn, and sticky corn. The sweet corn peeler can easily separate the seeds from the stalks. In addition, we also provide sheller machines for dry corn and multi-function sheller machines for sale. They are suitable for corns that have a water content ≤14%.

The sweet corn thresher machine is suitable for the quick-frozen food processing industry, corn canning factory, corn pulp juice quick-frozen, corn processing factory, agricultural by-products processing, and other industries.

For most restaurants, this type of fresh corn sheller machine is also a good device for helping them save labor and time. Besides, most of the gourmets think that freshly baked corn kernels taste better. If your restaurant pursues high-quality ingredients, this is a good choice for you.

We have one client who ordered this machine for their central kitchen, and their corn salad is in high demand even now. If you want to hear this story, click here: Sweet Corn Shellers Ordered By Orlando BBQ Restaurant.

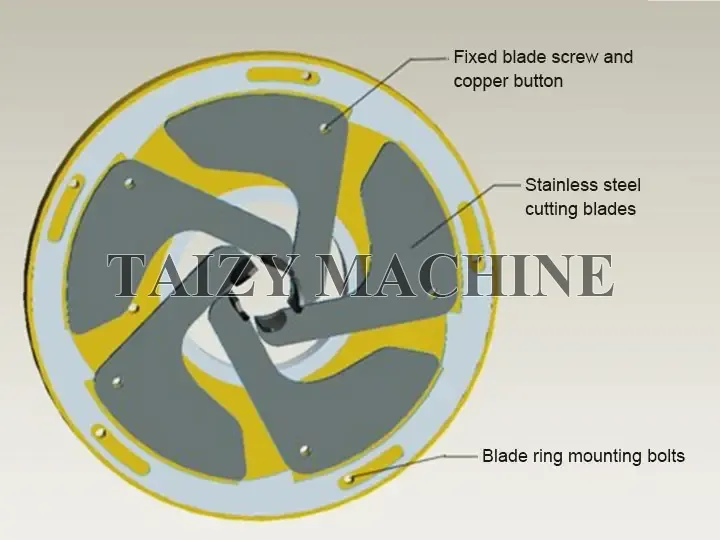

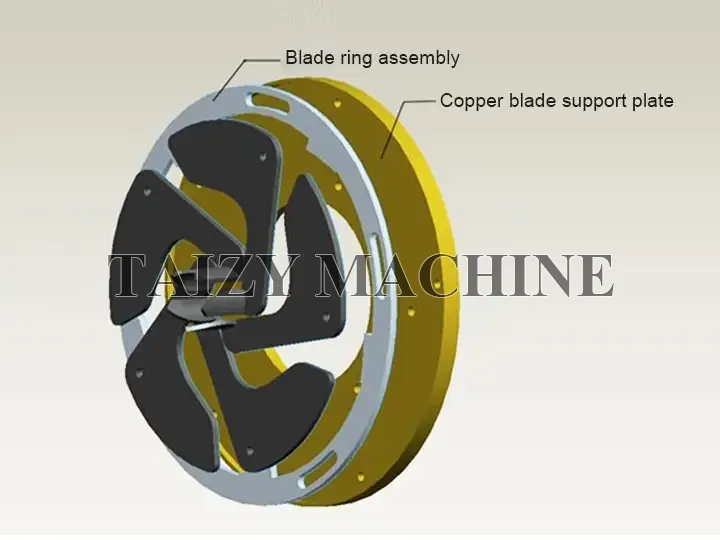

Advanced structure of sweet corn sheller

Sweet corn threshing machine mainly consists of a feeding part, a seed and cob separation mechanism, a cob export mechanism, a corn kernel discharge port, and an electrical control system.

- The feeding part is fed into the feeder by a stainless steel chain conveyor, with the head of corn facing forward. The conveyor uses a stainless steel chain to convey at an even speed. The feeder is composed of food-grade rubber rollers, which are soft and flexible and will not damage the outer skin of corn.

- The seed cob separation part consists of unique knives and cutter discs, which can easily cut corn cobs of different diameters. The blade rotates at high speed when working, which is close to the corn, and can handle bent corn cobs. The cutter can cut axially and radially, which greatly improves the yield of corn kernels.

This is the detailed interior design of the blade plate. and the blade plate, which is the most important part of this stainless steel fresh corn sheller machine. The next part will show you how to maintain such a machine, and when you face some problems while using it, how to solve them.

Precautions for fresh corn sheller machine usage

- The corn cobs used for threshing must be removed from their outer wrapping leaves and whiskers before being placed into the machine.

- After the daily operation, the staff must promptly clean up the knife plate and the feeding and discharging parts to avoid excessive corn juice sticking to the block and reduce the cutting efficiency.

- For a better stripping effect, the corn should preferably be intact, and the top of the corn should be removed. In addition, the length of the sweet corn should preferably be greater than 8 cm.

- The operator should follow the correct feeding procedure to allow the corn to be fed evenly to the feed chain. In case of persistent feed blockage, please inform the professional maintenance personnel immediately.

- Hands or any non-feedstock objects should not be placed on the feed opening. Otherwise, the fresh maize thresher machine’s blades will cause personal injury, and the machine will be severely damaged.

- To ensure the safety of personnel and the operation of the small maize sheller machine, only trained staff are authorized to operate, adjust, and maintain it.

FAQs of waxy corn thresher machine

Can the depth of corn cutting be controlled?

Yes, it depends on the frequency converter, which is always set at 40Hz-60Hz. And the faster the knife speed, the deeper the corn kernels are cut.

Can the speed of the machine processing corn be controlled?

Yes, the rotational speed of the knives is controlled by the inverter, and the conveyor speed is fixed.

What should I do if the feeding process is blocked?

If the machine is blocked or jammed with corn, you should stop the machine first and then press the reverse button to let the corn exit in reverse.

What is the price of the sweet corn peeler?

The cost of this machine is a few thousand dollars, and it will add the price for shipping, packing, and other customized devices.

How much will it cost if you want to buy a fresh corn sheller machine?

The whole price will be a couple of thousand dollars, which includes shipping cost, the price of the machine itself, and some wearing parts. But we provide worldwide shipping and even door-to-door transportation.

Our voltage can be customized according to different regions, and the cost is less than $200. Normally, within 7 working days after receiving payment, our factory will begin production of the machine. But if you don’t have many special needs for the machine, we have spot goods for emergencies.

If you want to get free consultations on the exact prices of this type of Fresh corn sheller machine, don’t hesitate to contact us!