Maize Grits Making Machine | Corn Grits Milling Machine

| Model | T1,T3, C2, PD2,PH |

| Raw materials | Dry corn kernels |

| Capacity | 300-450kg/hour |

| Hot sell countries | Philippines, the US, Nigeria |

| Products | grits and corn flour |

You can now ask our project managers for technical details

This maize grits making machine can peel and grind corn kernels and make them into grits and corn flour, with an effective output of 300-400kg/h. The final products are: large grits <14 mesh, small grits 14-40 mesh, and cornmeal >40 mesh.

There are five models of corn grinder machines for sale. Their output and accessories are different, but the finished product and fineness are the same. We still provide a type of stainless steel corn grinding machine to meet your food grade hygiene requirements.

This is a feedback video of the corn grits machine from our Philippine clients who apply this equipment on their farm.

Advantages of maize grits making machine

- The corn grits machine has multiple uses. Especially the model of T1, which can not only process corn, but also process wheat, rice, sorghum, and other grains. (grinding rice: 400kg/h, wheat peeling: 400kg/h, grinding wheat flour: 200kg/h)

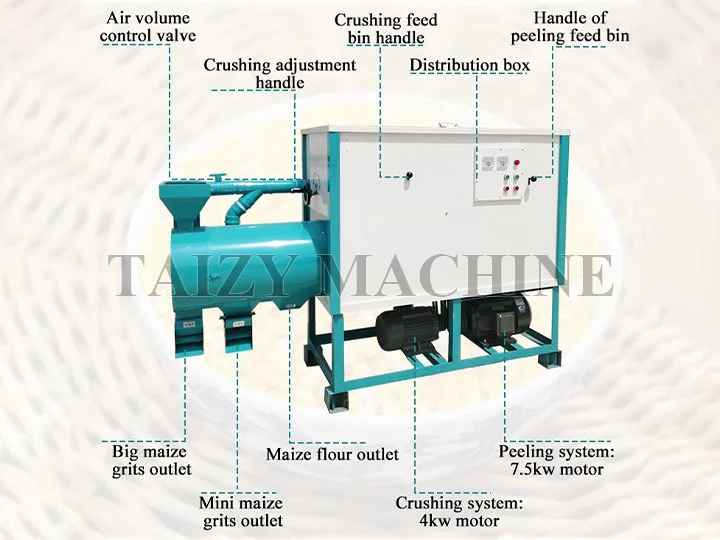

- Taizy corn grits making machine has two electric motors(7.5 kW&4 kW). The installation of double motors can keep the peeling system and the grinding system working simultaneously, which greatly improves efficiency.

- By adopting a cyclone dust collector, the finished corn kernels produced by the corn grinder machine do not contain waste and dust. With high output, it is an excellent deep processing machine for corn and grains.

- The corn grits grinder uses high-voltage electrostatic spraying to effectively protect its machine casing, prolonging its life. It can also be customized with 304 stainless steel as its material to provide long-term protection.

- Our factory provides many kinds of corn grits-making machines, with many choices to meet the different requirements of various customers. Some types can choose the matching double elevator for full automation without any other operation.

Raw materials and final products

This maize grits making machine uses dry corn kernels as raw material, which completes the corn cleaning, hulling, germ removal, crushing, grinding, and grading processes. The final product is corn grits of varying particle sizes, of corn grits and corn flour. The typical ratio is 5:4:1(large grits: small grits: cornmeal), but this ratio can be adjusted to suit your desired product quantity.

The final product has many applications: the waste from the first peeling can be used as livestock feed, the corn grits can be processed into processed foods, or just be sold directly to local supermarkets and food factories.

Hot-selling maize grits machine

Model one: TZ-T1 grinding corn machine

The maize grits making machine is mainly composed of five parts: peeling part, grits making part, three separators, fan, and frame. The grits-making machine and the peeling machine can work at the same time. The grits are made by the three separators below, which can divide the corn into three kinds of finished products: big grits, medium grits, and flour, and the corn grits will be polished naturally.

| Model | TZ-T1 |

| Corn peeling output | 350-450kg/h |

| Making corn grits capacity | 1000kg/h |

| Making corn flour speed | 350kg/h |

| Rated voltage | 380V |

| Power | 7.5kW 4 pole |

| Spindle speed | 1150r/min |

Model two: TZ-T3 maize grits making machine

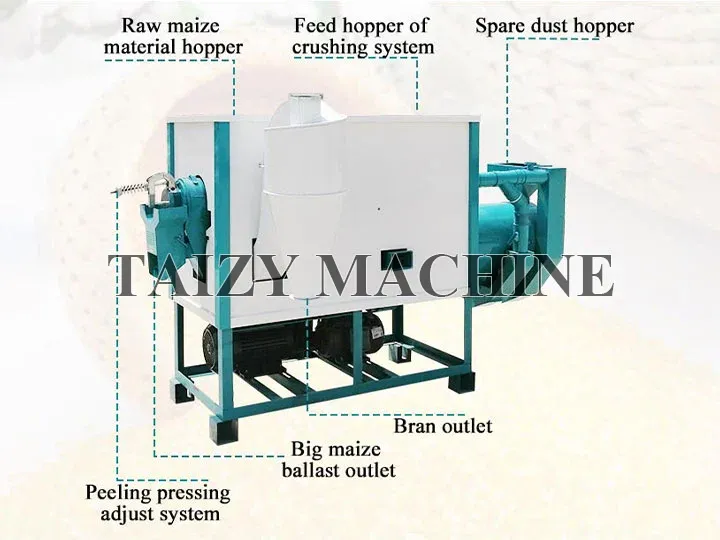

The maize grits making machine is composed of a peeling system, calcium system, finished product grading system, dust removal system, frame, and a newly added automatic adjustment system of discharge and power distribution system, which can ensure the machine operation always in the best working condition.

It needs two steps to use this grit grinder, so for more convenience, we provide an elevator for automatic loading and feeding, achieving full automation, greatly saving labor time.

| Model | T3 |

| Capacity | 300-400kg/h |

| Power | Electric motor (7.5kW & 4kW) |

| Weight | 680kg |

| Size | 2300*1400*1300mm |

Other models:

1. TY-PH maize flour grinding machine

This type of maize grits making machine has a peeling precision adjustment system, which is different from other types. In addition, its operation is simpler, with a lever instead of a button. What’s more, it also has a secondary spare dust hopper to make the raw materials cleaner.

2. TY-PD2 corn grits machine

This machine has a higher degree of automation than other models and is suitable for food processing plant production lines that have high requirements for output and efficiency.

3. C2 maize grits making machine

This machine has a viewing port, which allows you to see the internal processing process of the machine and and you can adjust the processing speed according to the machine’s operating conditions.

If you don’t know which machine can meet your real needs, please contact us. Our service staff will recommend the most suitable machine according to your actual situation

How does the maize grits making machine work?

Step 1: First grinding

Close the feed inlet and pull the feed board, then start the motor. After normal operation, slowly pull off the material to send the plug board.

Step 2: Second grinding

Then pour into the hopper to start production. Production can adjust the outlet pressure board to control the sizes of products. The pressure plate should be reduced during the first pressure and increased during the second pressure until the desired effect is achieved.

Step 3: End operation

When the processing is about to end, the locking handle should be loosened, and the adjusting handwheel should be quickly rotated out. At this time, the grinding head and the grinding core have been separated.

Note: If you feel that the finished product does not meet your requirements, you can process it multiple times.

Successful cases of maize grits making machine

Congratulations! Last month, we exported a corn grits machine to the United States. The customer has a local factory that is engaged in corn processing and needs a machine to make corn kernels into corn grits and sell them.

After understanding his requirements, Winnie, our account manager, showed him photos and videos of different maize grits making machines in action, advantages, etc. After reading the information, the American customer was more interested in the T1 model of the grits machine and quickly placed an order.

After receiving the machine, he immediately put it into production. With the addition of the new machine, the output and efficiency of his corn processing plant have been greatly improved.

“If I need to expand production in the future, I will definitely order a few more of your corn processing machines. The results and quality are amazing.” Our customer excitedly shared his experience with us.

FAQ about maize grits making machine

What is the fineness of finished products?

Large grits: <14 mesh, small grits: 14-40 mesh, cornmeal: >40 mesh

How about the motor power?

There are two motors, 7.5KW+4KW, so corn peeling and corn crushing can work simultaneously.

Can I close the other outlets if I only want flour or grits?

No, you can’t have just one or both finished products alone. The three finished products are in proportion to the output, and if you want more of a certain product, you can adjust the proportion.

Can the thickness of corn peeling be adjusted?

The peeling thickness can be adjusted by the pressure-adjusting handwheel.

What are the specific steps of the maize grits making machine?

Step 1: corn peeling, divided into flaps.

Step 2: grinding into large grits, small grits, and cornmeal

General fault analysis and treatment of maize grits making machine

1. Corn peeling is not clean

There are some things you should know to make sure: What is the moisture content of corn? (It should be within 15%.) Are the cylinder and screen seriously worn? (If it is because of such a reason, change the damaged parts.)

2. More kernels and lower seed yield of broken corn

It may be caused by the increase in pressure resistance of the stripper due to wear. If so, the stripper needs to be replaced. It may also be that the speed is too high when processing. Just reducing the speed will solve such problems.

3. Unevenly finished grits or low cornmeal yield

Most of the new machines have similar phenomena, which can only be eliminated after a period of time.

4. Three types of grits mixing

The gap between the bottom of the basket and the three separate shells is too large. Just plug the arc gap with a cloth strip will solve it. And have a check that if there is a crack in the rag, sewing or replacing it will be okay.

If you still have any other problems with this machine. Welcome to consult us for the answers.

Automatic maize girts making machine unit

There is a complete corn grits making machine unit to process corn from the first step of cleaning to the final step of grinding. The whole corn grinder machine makes your work easier and simpler, which is a perfect production line for food processing plants.

It consists of four main parts: a corn cleaning machine, a silo, a maize peeling machine, and a T3 corn grits machine. In terms of saving manpower and time, it’s an excellent option for corn processing.

Want to know more information about this machine line? Contact us to gain it.