Automatic Sweet Corn Cutting Machine For Processing Fresh Maize

| Model | TZ-100 |

| Power | 2.5-3 KW |

| Voltage | 380 V |

| Application | Fresh corn, sweet corn, frozen corn, carrot, etc. |

| Capacity | 2000-3000 pcs/h |

| Maz cutting size | 25 mm |

You can now ask our project managers for technical details

Taizy fresh corn cutting machine can mainly cut glutinous corn, sweet corn, frozen corn, and other foods of similar shape and hardness(carrots, yams, and cassava). Its max cutting size is 25mm, with an output that can reach 500kg-600kg per hour.

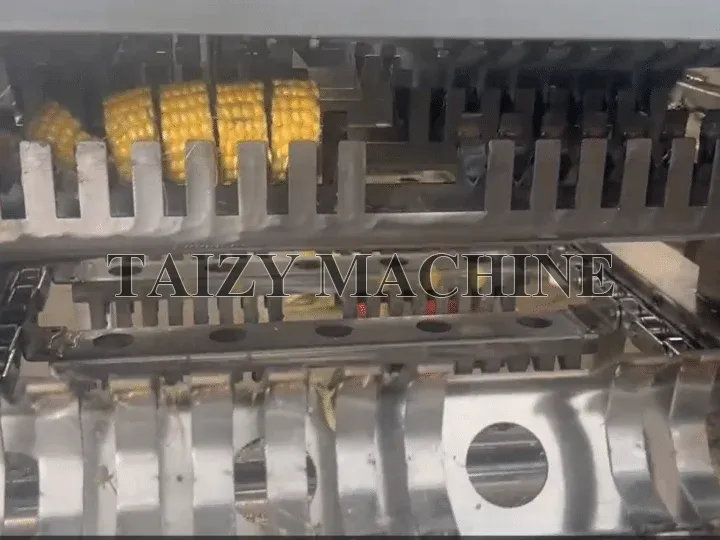

There are two types of corn cutters: single-row corn cutters (can produce 1500 corns per hour) and double-row corn cutters (can process 3000 corns per hour).

This type of corn cob cutter machine is widely used in food processing plants, effectively assisting the automation of production processes. We have exported to Vietnam, the United States, Singapore, and other countries. Almost all our clients provide us with positive feedback on achieving their factory assembly line production goals.

How does this fresh corn cutting machine work?

The first step of the maize cutting operation is checking. Three points need to be paid attention to:

- Is the conveyor belt running smoothly without any obstruction?

- Is the blade working properly? Test it by putting one whole corn in it first.

- Do not cut corn with the skin on.

Then you can run it normally as one part of your production line.

Key features of sweet corn cutting machine

- Most parts of it are made of SUS304 and GB grade food-grade stainless steel. The corn cob slicer is easy to clean and has a long service life.

- Besides just cutting frozen, fresh, and aged corn, it is also suitable for carrots, yams, cassava, and other types of food.

- The cutting length is adjustable to ensure precise cutting, making it suitable for mass-producing finely packaged foods. The complete corn cob can be divided into two or more sections, which can also be changed.

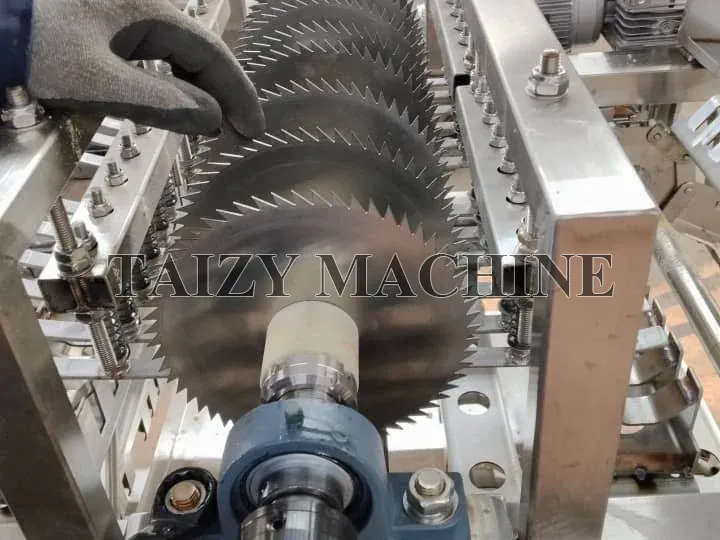

- It utilizes high-quality manganese steel circular blades for precise cutting and a smooth blade surface. The finished product has a neat appearance with no material spillage.

- This corn cutter equipment offers high production efficiency, with an hourly output of 500-600 kg, which can meet the needs of most industrial production.

Corn cob slicer’s parameters

| Model | TZ-100 |

| Power | 2.5-3 KW |

| Voltage | 380 V |

| Mesh belt effective width | 400 mm |

| Maz cutting size | 25 mm |

| Capacity | 2000-3000 pcs/h |

| Measurement | 2130*1170*1360 mm |

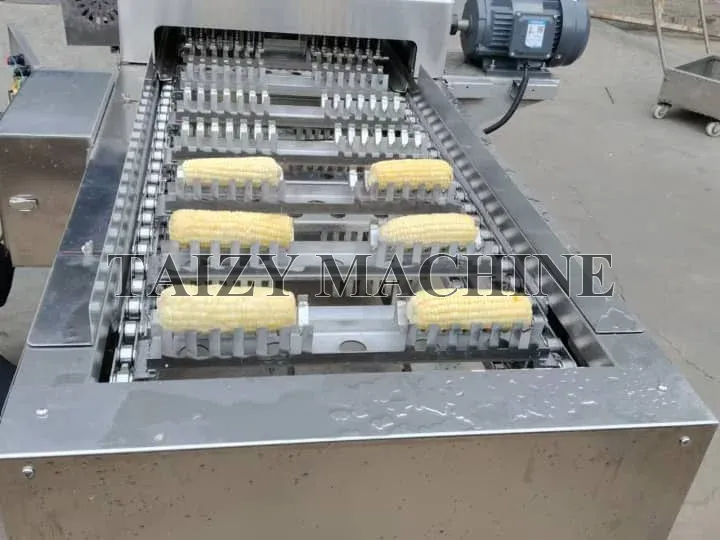

| Number of trays | 21 sets × 2 pcs each |

Note: The Cutting length of the corns can be customized, but no less than 2.5 cm. If you want to cut two sizes of corn segments, you can change the blades. But if the sizes of corn segments that you need can not form a multiple relationship, you need to buy one more corn cutting machine.

For example, one machine can process 2.5cm, 5cm, and even 7cm corn segments. But if you want to cut other sizes, you should purchase another machine to process 3cm, 6cm corn segments.

Main structure of the corn cob cutter machine

There are two main systems of this automatic corn cutting machine to finish the whole process: the cutting system and the transmission system.

The most important part of the cutting system is the sharp stainless steel blade, which has a different power supply from the whole machine running, needing an extra motor with the power of 3KW.

The transmission system has a total of 21 sets of trays (each has 2pcs) with the function of fixing corn cobs and effectively reducing working time.

Successful case of shipping the corn cutters to a Vietnamese corn processing plant

Our client is a corn processing factory in Vietnam, specializing in fresh corn and corn-based products. The factory handles a large volume of corn every day. To improve productivity and product quality, the client was looking for a high-efficiency, precise, and flexible corn cutting solution.

During communication, the customer provided clear technical requirements about the cutting size, power supply, and installation support.

Based on the requirements, we supplied two customized Corn Cutting Machines:

- Two machines customized: 2.5 cm / 5 cm cutting machine and 3.5 cm / 7 cm corn cob slicer.

- Equipped with a quick-change knife and shaft design, ensuring flexible and efficient size adjustments.

- Built with food-grade stainless steel, meeting food safety standards.

- Delivered with complete manuals, drawings, and training videos to help the customer quickly get started with installation and knife replacement.

Through this project, we helped our Vietnamese customer successfully upgrade their mechanized and standardized processing solutions, which greatly increased the output of their factory. We have received good feedback from him!

If your factory needs an improvement for a higher level of automation, this fresh corn cutting machine is a good choice! Contact me now to get the latest quota and information!

Taizy also provides a fresh corn sheller machine for corn kernel food processing. If you are interested in such a machine, click it to learn more details!