How Do Baler Wrappers Boost Silage Profits in Burkina Faso?

In Burkina Faso, the livestock industry continues to expand, resulting in a growing demand for stable and nutritious silage. Elephant grass and millet leaves are widely used as feed ingredients, but due to a lack of proper packaging, farms often face problems with high feed spoilage rates and limited storage capacity.

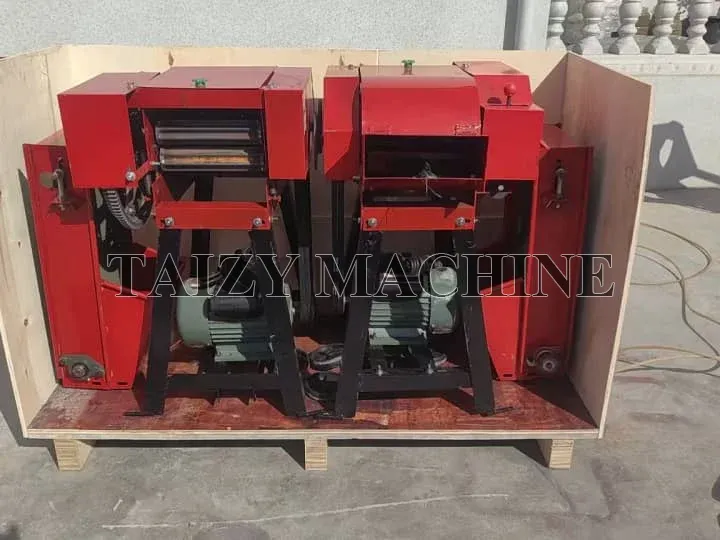

To address these challenges, local farms collaborated with Taizy to introduce a batch of balers and accompanying crushers, thereby improving the silage processing process and enhancing overall profitability.

Challenges for farmers in Burkina Faso

Before adopting baling technology, farms in Burkina Faso faced many unresolved problems that severely affected the quality of their forage and the profits they ultimately earned.

- High Silage Loss Rate: During transportation and storage, fresh elephant grass, if loosely packed or improperly compressed, can lead to mold growth and fermentation failure. In hot climates, feed losses can typically reach 20% to 30%.

- Short Storage Period: Unpackaged silage can only be stored for a limited time, making it difficult to maintain a stable feed supply during the dry season and hindering its transportation to other regions for sale at higher profits.

- Low Transportation Efficiency: Bulk silage is bulky and difficult to transport, and unavoidable losses during transportation are common, with losses amounting to at least 10% of the total sales revenue.

- Low Added Value: Due to the lack of proper packaging, silage cannot be sold at higher prices in more regions. Many local customers prefer packaged silage, and the lack of proper packaging results in significant lost orders.

How do Taizy baler wrappers solve these problems?

To address their needs, we provided a solution consisting of a TZ-55-52 baler and wrapper machine paired with a chaff cutter.

Both of them are equipped with wheels for easy mobility, allowing them to be moved freely around the work area. The forage chopped by the chaff cutter is directly fed into the baler and wrapper machine for packaging.

The main advantages of using a baler wrapper include:

- Excellent sealing, improving fermentation quality

- Standardized bale size, facilitating handling and storage

- Film wrapping protects the silage from moisture and oxygen

- Compact bales reduce storage space and transportation costs

Significant profit increase after using balers

Farms in Burkina Faso have achieved significant economic benefits after using Taizy baler wrappers:

- Silage loss rate decreased from over 20% to less than 5%, saving on raw material costs.

- Baled silage can be stored for 6-12 months, ensuring a year-round feed supply.

- The compact bales reduced transportation volume by approximately 40%, greatly improving transportation and sales.

- Selling baled silage increased farm income related to silage by approximately 20%-30%.

If you frequently experience difficulties with forage storage and transportation, consider using machinery to solve the problem. A single machine can last for at least three years and can bring you an additional 30% to 40% in profits.

Want to receive the latest complete price quote for this baler wrapper? Please contact us. Different offers and promotions may be available at different times! More machine details are here: Hay Baler Silage Machine.