मक्का सिलेज बेल बैलर मशीन

घास बैलर सिलेज मशीन | चारा बैलर

मॉडल: TZ-55-52, 9YDB-55।

क्षमता: 50-65 बेलें/घंटा

बेल का आकार: φ550×520 मिमी

बेल का वजन: 65-100 किलोग्राम/बेल

कोटिंग परतों की संख्या: समायोज्य

आवेदन: घास, मकई stalk, सिलेज, घास आदि।

हॉट सेलिंग देश: नाइजीरिया, संयुक्त अरब अमीरात, अर्जेंटीना, आदि।

मक्का साइलोज़ बेलर विशेष रूप से साइलोज़ और हेज़लैज बेलिंग के लिए डिज़ाइन किया गया है, जो गोल बेलों के लिए स्थिर, वायु-बंद पैकेजिंग प्रदान करता है। यह φ550 × 520 मिमी आकार के बेलों के लिए उपयुक्त है, जिनका वजन 65 से 100 किलोग्राम के बीच है।

इसकी फिल्म रैपिंग गति 50-65 बेलें/घंटा तक पहुंच सकती है, जिसमें 2-स्तरीय फिल्म के लिए 13 सेकंड और 3-स्तरीय फिल्म के लिए 19 सेकंड का रैपिंग समय है, जो हाय बेलिंग की दक्षता को काफी बढ़ाता है। यह थाईलैंड, केन्या, अमेरिका और अन्य देशों में साइलोज़ संरक्षण के लिए व्यापक रूप से लोकप्रिय है।

ताइजी सिलेज बैलर मशीन के लाभ

- कई उन्नतियों के बाद, हमारी रैपिंग फिल्म घनी है और प्रभावी रूप से हवा को अलग करती है, जिससे रैप किए गए सिलेज बैल 1-2 वर्षों तक प्राकृतिक किण्वन के बाद संरक्षित रह सकते हैं।

- यह बैल रैपर समायोज्य रैपिंग परतें प्रदान करता है, जिससे आप हाफ-टर्न कंट्रोलर को समायोजित करके 2, 3, 4, या 6 परतें चुन सकते हैं, जो सीलिंग की डिग्री को स्वतंत्र रूप से नियंत्रित करता है।

- हमारी घास बेलर मशीन का नवीनतम संस्करण एक पूर्ण स्वचालित कन्वेयर बेल्ट से लैस है, जो सुविधाजनक और तेज़ फीडिंग प्रदान करता है ताकि कार्य दक्षता में सुधार हो सके। कुछ उन्नत मॉडल में अतिरिक्त बेल्ट भी शामिल है ताकि बेलिंग प्रक्रिया के दौरान गिरने वाली सिलेज को इकट्ठा किया जा सके।

- ताइजी सिलेज पैकेजिंग मशीन पावर स्रोत चयन, रंग विन्यास, और वोल्टेज सेटिंग्स सहित अनुकूलन विकल्पों की एक श्रृंखला प्रदान करती है।

स्व-लोडिंग बैल रैपर उन्नयन और अनुकूलन सेवाएँ

उच्च-गहन कृषि संचालन और विभिन्न कार्य वातावरण की आवश्यकताओं को पूरा करने के लिए, ताइजी का स्व-लोडिंग बैलिंग और रैपिंग मशीन संरचना, सामग्री, और संचालन स्थिरता के संदर्भ में व्यापक रूप से उन्नत किया गया है।

- हमारे बैल रैपर के टायर छोटे रबर टायर से बड़े, ठोस टायर में अपग्रेड किए गए हैं, जो अधिक टिकाऊ और पंचर प्रतिरोधी हैं, जिससे ऑपरेशन के दौरान टायर फटने का जोखिम समाप्त हो जाता है।

- इसके फ्रेम संरचना को भी अपग्रेड किया गया है, 4×4 सेमी स्टील संरचना से 5×5 सेमी स्टील संरचना में, जिससे लोड-बेयरिंग क्षमता बढ़ती है और इसकी सेवा जीवन बढ़ती है।

- ब bearings को टाइप 203 से टाइप 204 भारी-ड्यूटी bearings में अपग्रेड किया गया है, जिसमें bearings के बीच एक मोटा केंद्रीय शाफ्ट है, जिससे पहनने की दर कम हो जाती है और विफलता का जोखिम काफी हद तक कम हो जाता है।

- हमारा अपडेटेड सिलेज फीड बैलर पिकल्ड से बना है। ठंडा-रोल्ड स्टील प्लेट, उत्कृष्ट जल प्रतिरोध, नमी प्रतिरोध, और सिलेज प्रतिरोध के साथ, यह दीर्घकालिक बाहरी उपयोग और उच्च आर्द्रता वाले वातावरण के लिए आदर्श है।

- कन्वेयर बेल्ट और स्वचालित फीडिंग नियंत्रण को अपग्रेड किया गया है। कन्वेयर बेल्ट अब स्वतंत्र चेन सिस्टम द्वारा संचालित है, और एक हाइड्रोलिक सिलेंडर जोड़ दिया गया है जो कन्वेयर बेल्ट की गति को स्वतंत्र रूप से नियंत्रित करता है, जिससे अधिक सटीक फीडिंग नियंत्रण और सुरक्षा सुनिश्चित होती है।

सिलेज बैलर मशीन के मॉडल और पैरामीटर

हमारे ग्राहकों की विविध आवश्यकताओं को पूरा करने के लिए, हम मशीन मॉडल की एक श्रृंखला प्रदान करते हैं। नीचे हमारे कुछ सबसे अधिक बिकने वाले मॉडल और उनकी विशिष्टताएँ दी गई हैं।

| मॉडल | TZ 55-52 | 9YDB-55 |

| बैल की गति | 50-60 पीस/घंटा, 5-6 टन/घंटा | 50-65 पीस/घंटा, 5-6 टन/घंटा |

| पैकेज आयाम | φ550×520 मिमी | φ550*520 मिमी |

| पैकेज वजन | 65-100 किलोग्राम/बैल | 65-100 किलोग्राम/बैल |

| पावर | 5.5 0.55 किलोग्राम | 5.5 0.55 किलोग्राम |

| कोटिंग परतों की संख्या | 2-6 | PLC नियमन |

| रैपिंग दक्षता | 13 सेकंड/2 परतें 19 सेकंड/3 परतें (प्रति बंडल) | 18 रिंग/2 परतें 26 रिंग/3 परतें 37 रिंग/4 परतें (प्रति बंडल) |

| मशीन का आकार | 3380*1370*1300 मिमी | 3500*1500*1600 मिमी |

घास बैलर के बैलिंग और रैपिंग प्रदर्शन

विभिन्न चारे की स्थिति के अनुसार बैलिंग और रैपिंग सेटिंग्स अलग हो सकती हैं। इस आधार पर, ताकि हमारे ग्राहक एक मशीन का उपयोग कई उद्देश्यों के लिए कर सकें, हमारी मशीन को चारे की लंबाई और बैल संरचना के अनुसार लचीले ढंग से समायोजित करने के लिए डिज़ाइन किया गया है।

नीचे चारे की लंबाई के आधार पर अनुशंसित ट्वाइन टर्न्स और ट्वाइन पुली चयन के लिए मार्गदर्शिका दी गई है।

| घास की लंबाई की स्थिति | अनुपात | ट्वाइन टर्न्स |

| 50–≤200 मिमी (अधिकतर लंबी घास) | 80% | 9–10 टर्न्स |

| 20–≤100 मिमी (छोटी घास मिश्रित) | 50% | 12–14 टर्न्स |

| ट्वाइन टर्न्स | चारे की स्थिति | ट्वाइन पुली |

| 12–14 | छोटी घास की मात्रा अधिक है | बड़े व्यास का पुली |

| 9–10 | लंबी घास या सूखी घास | छोटी व्यास का पुली |

यदि आप निर्धारित नहीं कर पा रहे हैं कि कौन सा कॉन्फ़िगरेशन आपके लिए सबसे उपयुक्त है, तो आप हमें अपने कच्चे माल और आवश्यकताओं को भेज सकते हैं, और हमारी बिक्री टीम आपकी विशिष्ट आवश्यकताओं के आधार पर सबसे पेशेवर मूल्यांकन प्रदान करेगी।

चौकोर बैलर के उपयोग के लिए प्रभावी और स्पष्ट संचालन प्रक्रियाएँ

चरण 1: शुरू करने से पहले तैयारी

ऑपरेशन से पहले, ऑपरेटर को चारे की स्थिति का आकलन करना चाहिए। यह भी आवश्यक है कि बैल रैपर के उपयुक्त पुली व्यास और बंधन रस्सी के लूप की संख्या का चयन किया जाए। फिर बंधन रस्सी को रस्सी गाइड सिस्टम और पुली के माध्यम से threaded किया जाता है।

एक बार रस्सियाँ तैयार हो जाने के बाद, बैलिंग चैम्बर को बंद और लॉक करना चाहिए। संलग्न बैलिंग चैम्बर बैल के निर्माण के लिए एक नियंत्रित स्थान प्रदान करता है। यह तैयारी प्रक्रिया का दूसरा चरण है।

इसके पैकेजिंग सिस्टम को भी फीडिंग शुरू होने से पहले तैयार करना चाहिए। स्ट्रेच फिल्म को फिल्म होल्डर पर स्थापित करना चाहिए, फिल्म टेंशन और प्री-स्ट्रीचिंग सिस्टम की जांच करनी चाहिए। रैपिंग की परतों की संख्या (2, 3, 4, या 6 परतें) को हाफ-टर्न कंट्रोलर को समायोजित करके पूर्व निर्धारित किया जाना चाहिए।

चरण 2: गोल बैलर और रैपर का बैलिंग प्रक्रिया

चारे की बैलिंग का सिद्धांत बहुत सरल है: सामग्री को समान रूप से संकुचन कक्ष में डालें, और फिर मशीन चारे को घुमाकर गोल बैल में संकुचित कर देगी। इस प्रक्रिया के दौरान, बैल की घनता धीरे-धीरे बढ़ती है जब तक कि यह निर्धारित आकार तक नहीं पहुंच जाती।

जब घास का बैल निर्धारित व्यास और घनत्व तक पहुंच जाता है, तो मशीन स्वचालित रूप से एक अलार्म संकेत भेजेगी, और जल्द ही सिस्टम बैलिंग चरण में प्रवेश करने की तैयारी करेगा। यह अलार्म अधिक भराव से रोकथाम करता है और बैल का आकार सुनिश्चित करता है।

बांधने की प्रणाली स्वचालित रूप से घुमावदार बैल के चारों ओर समान रूप से बंधन ट्वाइन लपेटती है, जो फिल्म रैपिंग प्रक्रिया से पहले बैल को सुरक्षित करता है। एक बार निर्धारित संख्या में लपेटने के बाद, बंधन ट्वाइन स्वचालित रूप से कट जाती है और अंतिम फिल्म रैपिंग चरण के लिए तैयार हो जाती है।

चरण 3: बैलर मशीन के रैपर प्रक्रिया

संकुचन कक्ष के अंदर, तैयार घास के बैल को आसानी से winding प्लेटफ़ॉर्म पर धकेला जाता है। फिर, स्ट्रेच फिल्म बैल को निर्धारित परतों में लपेटना शुरू कर देती है। जब winding पूरा हो जाता है, तो बैल पूरी तरह से सील हो जाते हैं और किण्वन या परिवहन के लिए तैयार होते हैं।

बैल पूरी तरह से डिस्चार्ज होने के बाद, संकुचन कक्ष स्वचालित रूप से रीसेट हो जाता है, और मशीन लोडिंग स्थिति में वापस आ जाती है, तुरंत अगली बैलिंग चक्र शुरू करती है। यह सतत कार्यप्रवाह उच्च दक्षता और स्थिर उत्पादन सुनिश्चित करता है, भले ही फसल कटाई के चरम समय में हो।

दो पूरक साइलोज़ बेलिंग समाधान

इसके अलावा, हमारे बैलर अन्य मशीनों के साथ मिलकर एक पूर्ण स्वचालित सिलेज बैलिंग लाइन बना सकते हैं। इन्हें बड़े पैमाने पर सतत बैलिंग के लिए साइलो के साथ या घास चॉप्टर के साथ इस्तेमाल किया जा सकता है।

1. साइलो के साथ साइलोज़ बेलर और रैपर

यह प्रणाली साइलोज़ के साथ उपयोग की जा सकती है ताकि बड़े पैमाने पर, निरंतर फीडिंग और बेलिंग की जा सके। साथ ही, साइलो फीडिंग सिस्टम मैनुअल फीडिंग से जुड़ी अस्थिर उत्पादन दक्षता से बचाता है, जिससे बेलिंग की गति में उल्लेखनीय वृद्धि होती है।

2. स्ट्रॉ चॉपर के साथ बेल रैपर मशीन

जब भूसी क्रशर के साथ उपयोग किया जाता है, तो बेलर एकीकृत क्रशिंग और बेलिंग समाधान बनाता है, जिससे कच्चे फीड सामग्री को क्रश और बेल किया जा सकता है। यह सामग्री संकुचन में सुधार करता है, किण्वन गुणवत्ता बढ़ाता है, और श्रम और प्रसंस्करण समय को कम करता है।

बेलर रैपर निर्यात के सफल मामले

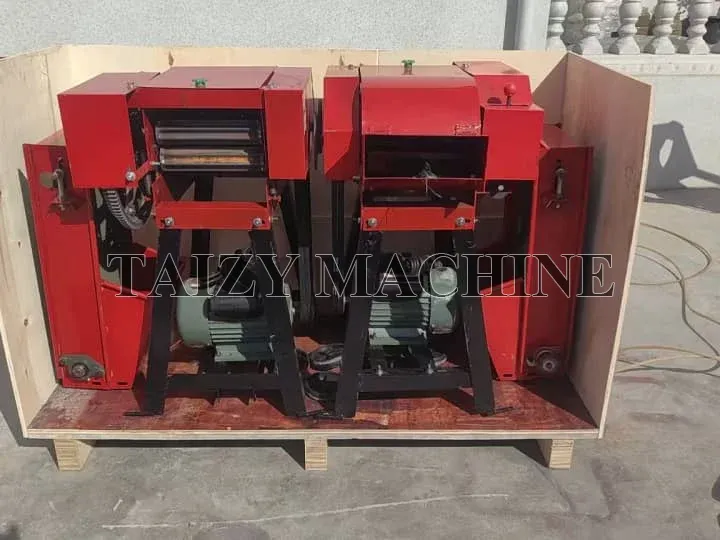

बुर्किना फासो के ग्राहकोंने दो सेट चारा कटर और रैपिंग मशीनें खरीदीं

ताइजी बुर्किना फासो के ग्राहकों को उनके पशुपालन उद्योग को विकसित करने में मदद करता है, जिससे वे अपने उच्च गुणवत्ता वाले साइलोज़ को स्थानीय स्तर पर संग्रहित और उपयोग कर सकते हैं, साथ ही इसे अन्य क्षेत्रों में भी परिवहन और बेच सकते हैं। बेलिंग और रैपिंग मशीन ने साइलोज़ बेचने से उनकी आय में महत्वपूर्ण वृद्धि की है।

मेक्सिको को भेजे गए 4 सेट मक्का साइलोज़ बेलर मशीनें

यह बैच की वस्तु मेक्सिको के एक ग्राहक द्वारा ऑर्डर की गई थी, जो एक बड़े पशुपालन फार्म के मालिक हैं और इस मशीन को चारे के भंडारण और परिवहन में सुविधा के लिए खरीदा है।

केन्या में वितरक को भेजे गए 5 सेट मक्का stalk बेलिंग मशीनें

केन्या से वितरक ने और 5 बेलर-रैपर मशीनें खरीदने का फैसला किया। यह हमारी तीसरी साझेदारी है। ये बेलर-रैपर मशीनें उत्कृष्ट मूल्य प्रदान करती हैं, उच्च गुणवत्ता वाली बेलें बनाती हैं, और स्थानीय स्तर पर बहुत लोकप्रिय हैं।

अंतिम मूल्य के लिए हमसे संपर्क करें। यदि आपके पास मशीन के बारे में कोई ऑर्डर आवश्यकताएँ या प्रश्न हैं, तो कृपया हमसे परामर्श करें।