Industrial Corn Husk Remover For Large Food Processing Factory

Sweet Corn Shucker | Maize Dehusking Machine

Model: 6BLQ-210-12000

Size: 10.5*1.72*1.95m

Weight: 5000kg

Capacity: 12000corns/h

Power: 12.25kw

Voltage: 380v

Breakage rate: 1%

Dehusking efficiency: 98%

Silk removal rate: 92%

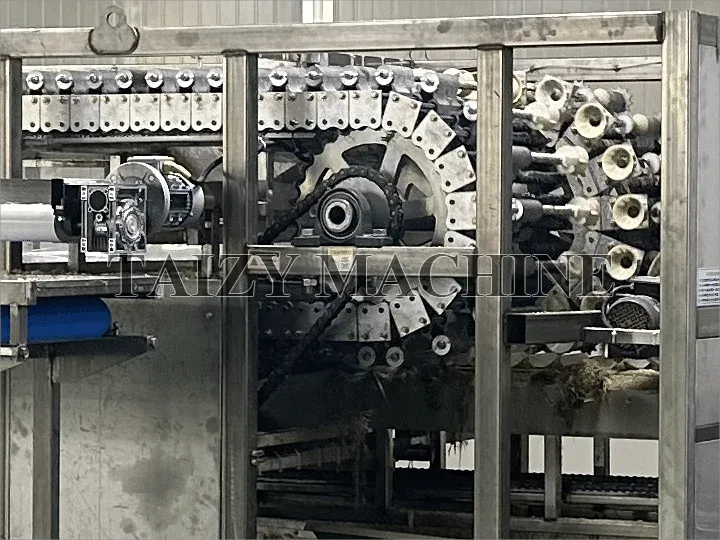

Taizy corn husk remover is specifically designed for automated food processing with integrated automatic root cutting, tip cutting, beard removal, air blowing to disperse leaves, and removing husk silks, etc.

The sweet corn shucker is capable of dehusking fresh, sweet, and waxy maize of any variety with a length of 110–280 mm (including husk and root) and a diameter of 40–80 mm (in husked condition). With a breakage rate of ≤1%, a shucking efficiency of ≥98%, and silk removal rate of ≥92%, its capacity can be up to 10,000–12,000 ears/hour.

Work video of industrial corn husk remover

Below is a video of customer feedback where we received the machine and did some testing.

Strengths of fresh corn husk remover

- This automatic corn shucker perfectly solves the problem of insufficient yield of fresh corn in large-scale processing and can process 10,000–12,000 fresh corns per hour, which improves the efficiency of the food processing production line.

- Taizy maize cob shucker machine includes husk peeling, root trimming, tip cutting, and silks removing. During the production process, there is no contact with pollution sources such as oxidized metals and moisture, which effectively ensures the quality and hygiene level of fresh glutinous corn products.

- The corn husk remover is capable of handling fresh maize of various varieties, with lengths from 110–280 mm and diameters from 40–80 mm, including sweet and waxy corn, making it highly versatile.

- Manufactured with industrial-grade materials and high-quality components, it offers stable operation and long service life, making it suitable for heavy-duty production.

Technical parameters of automatic sweet corn husk remover

| Model | 6BLQ-210-12000 |

| Size | 10.5*1.72*1.95m |

| Weight | 5000kg |

| Capacity | 12000corns/h |

| Power | 12.25kw |

| Voltage | 380v |

| Breakage rate | 1% |

| Dehusking efficiency | 98% |

| Silk removal rate | 92% |

| Application | Fresh corn, sweet corn, waxy maize,etc. |

Sweet corn husk remover working principle

The fresh corn husking machine removes the outer husk and silk of corn cobs through a combination of friction and stripping functions. During operation, the cobs are fed into the husking section by the conveying system one by one, where rotating rollers or specialized peeling devices apply pressure and friction to peel off the husk layer by layer.

At the same time, there are some auxiliary components, such as brushes or blowers, that help to effectively remove corn silk. Be equipped with a cutting mechanism that trims the base and tip of the cob, ensuring uniform length and a clean, smooth appearance without husk and silk.

Application of this type of corn dehusking machine

As the first step of processing corn food, the corn husk remover is key equipment to ensure the product quality. It helps achieve clean and uniform corn cobs that are ready for further processing or direct consumption. So it is suitable for quick-freezing production lines, vacuum-packed sweet corn production, post-harvest processing to reduce labor and increase product value, and other food processing industries or large farms.

Why choose Taizy maize husking machine?

- Taizy manufactures corn husk removers in our own factory, which ensures stable quality control, reliable supply capacity, and competitive pricing without relying on middlemen.

- We provide clear operation manuals, training videos, and online technical support. For overseas customers, spare parts and remote guidance are available to help keep the machine running smoothly and solve any problems you encounter.

- With years of experience in agricultural machinery manufacturing and export, Taizy has established a reputation for practical, user-oriented machines. We focus on durability, ease of operation, and practicality to meet the diverse requirements of producers of all sizes.

- Many customers from Asia, Europe, and America have stated that Taizy corn shellers have helped them save labor, reduce processing costs, and achieve stable yields. Their feedback motivates us to continuously improve our design and service.

Taizy also provides other equipment to be used in fresh corn processing:

- Sweet corn peeler machine: It can peel kernels from the corn cob by applying to corn cans or a frozen kernels production line.

- Fresh corn cutting machine: This is used to cut corn into pieces for the next processing steps.

If you want to know more information, click the website or contact me to ask about your needs.

Want to learn more about the price and details? Don’t hesitate to contact me!