Industrial Corn Dryer Machine | Grain Dryer for Sale

| Brand name | Taizy Machinery |

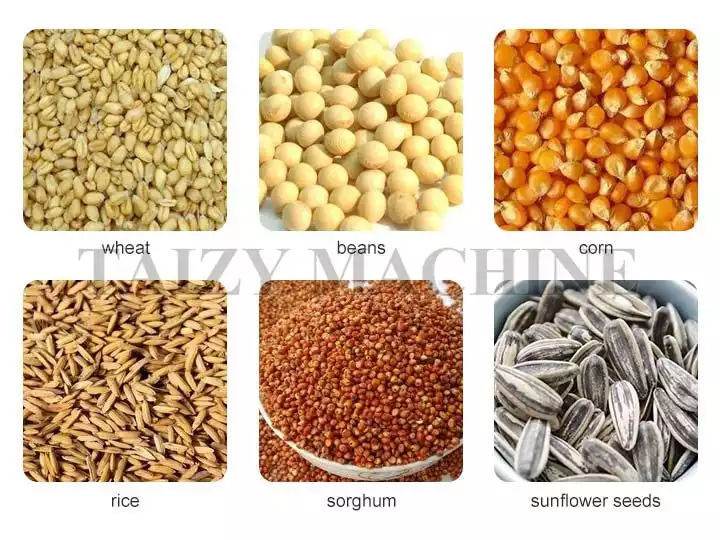

| Applicable raw materials | beans, wheat, corn, rapeseed, sorghum, millet |

| Capacity (kg/h) | 315-31800 (according to grain type and dryer model) |

| Model | 5H-10, 5H-13, 5H-15, 5H-32 |

| Suitable fuel | Biomass (branches, rice bran, straw, etc.), anthracite, oil, gas, gas, hot gas. |

You can now ask our project managers for technical details

In order to store grain well and prevent mold, an industrial corn dryer machine is needed to remove excess moisture from the grain. Taizy Machinery offers a new grain dryer and welcomes your inquiries.

This large industrial machine is specifically designed for grain drying and processing. It has a wide range of applications and can efficiently dry crops such as corn, wheat, and rapeseed. With a processing capacity of 15 tons per hour, it can effectively solve grain storage problems in shoort time.

Industrial corn dryer machine advantages

- The grain dryer adapts a wide range to wheat, corn, sorghum, soybeans, rice, sunflower seeds, millet, rapeseed, and other crops.

- The industrial corn dryer machine saves power. It has a daily output of 50 tons, and its total power is 7.6KW, which can be used with general agricultural electricity, without the need to install additional transformers.

- The grain dryer’s drying speed is fast, meanwhile its crushing rate is low. The dryer improves the relevant parameters and the grain running direction, besides, it maximizes the grain to be heated evenly.

- Low thermal energy consumption of the maize dryer machine. The dryer adopts the mode of low temperature, constant temperature, and fully enclosed drying to improve the heat utilization rate. The final dried grains have the same moisture table and a long preservation time.

- The dryer has a wonderful appearance, and the paint surface adopts electrostatic spraying and baking paint process, which is more than 5 times the general spray paint life.

Introduction of the corn drying machine

Taizy Machinery’s new corn drying machine can dry various grains such as beans, sunflower seeds, corn, sorghum, wheat, millet, etc. by high-temperature treatment, and also kill insects. The industrial corn dryer machine raises the height of its fall, eliminates the original screw conveyor, and adopts wear-resistant and smooth stainless steel as the runner trough plate, thus ensuring that there is no collision when corn, sorghum, and other grains fall, and avoiding breakage.

Parameters of industrial corn dryer machine

| Model | 5HXG-15 |

| Structure | Fixed |

| Recycling style | Batch cycle |

| Weight | 3200kg |

| Batch processing capacity | 3000-15000kg(corn), 3000-15000kg(wheat), etc. |

| Overall dimension | 4288*2738*11700mm |

| Total power | About 6kw |

| Feeding time | About 63min |

| Discharge time | About 58min |

| Drying capacity | 15t /h |

Raw materials for grain dryer

The maize dryer machine can dry large grains, such as beans, wheat, corn, and sunflower seeds. The machine can also dry relatively small grains, for rapeseed, sorghum, millet, etc. The final dried crops can be ground by a hammer mill grinder.

The capacity of corn drying machine for different grains

Taking rapeseed, corn, wheat, and rice as examples, we display the different capacities and volumes of each model. If you have any questions about it, feel free to consult us.

| 5H-10 | 5H-13 | 5H-15 | 5H-32 | ||

| Rapeseed | Volume(kg) | 7500~10300 | 7500~13450 | 7500~14850 | 12000~31800 |

| Capacity (kg/h) | 473~1235 | 607~1456 | 675~1620 | 1000~3500 | |

| Corn | Volume(kg) | 7500~10450 | 7500~13400 | 7500~16300 | 12000~32000 |

| Capacity (kg/h) | 756~1261 | 971~1618 | 1080~1800 | 1000~3400 | |

| Wheat | Volume(kg) | 7500~10450 | 7500~13350 | 7500~16300 | 12000~32000 |

| Capacity (kg/h) | 315~756 | 4056~971 | 450~1080 | 1000~3250 | |

| Rice | Volume(kg) | 6500~8400 | 6500~10850 | 6500~15500 | 9000~30800 |

| Capacity (kg/h) | 382~916 | 493~1184 | 548~1315 | 2600 |

Heating methods of corn drying machine

The industrial corn dryer machine is suitable for a wide range of heating methods, including biomass hot air furnaces, diesel burners, gas burners, and air-to-air heat pumps.

Biomass hot air furnace is to burn biomass waste to produce heat, including burning branches, straw and other waste. It belongs to the environmental protection and energy-saving hot air furnace, which provides a heat source for the industrial corn dryer machine. It is equipped with the leading automatic constant temperature ventilation device to ensure the quality of grain and low cost of use, which is popular among investors.

If you use the burner, you can choose natural gas or national standard O# diesel as fuel according to the customer’s demand. We are equipped with a burner using imported Italian machines with double nozzle function, good atomization performance, fast heating, stable hot air temperature, and accurate temperature control.

Detailed structure of grain dryer

The conveyor belt of the elevator is made of a pure nylon canvas belt. The dustpan is made of virgin nylon plastic with good toughness.

The PLC control box adopts touch screen operation to display the fault positioning in time.

The internal material of the maize dryer machine is stainless steel, galvanized plate and thickened steel plate, which is wear-resistant and durable.

Stock display of grain dryer

If want a mobile grain dryer, i would like to introduce this one to you: mobile grain dryer, which is suit for processing small-scale of crops. For more details, please contact me via email or other means and let me know your specific needs.